Introduction | Certificate | Keypoint | Application | Spec | Property | Details in Catalog

INTRODUCTION

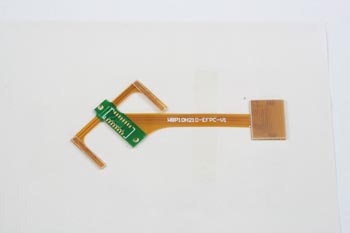

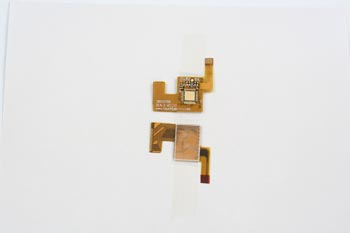

LEXFLEX 2L FCCL adhesiveless flexible copper clad laminates. It is also used as raw material of components where flexibility of various electronic products like mobile phones, LCD monitors and HDDs, which are frequently used in our daily life, is required.

CERTIFICATES

LEXFLEX 2L FCCL Certificate

Our FCCL already certificate by UL. Our file number could be search under UL Database (click to QMTS2.E466949). Also it is RoHS ready! More confident for customer choose LEXFLEX 2L FCCL as partner.

KEYPOINTS

LEXFLEX 2L FCCL is a sputter type with two-layers of FCCL, it is an electronic material required to make a product lightweight, and is fine-pitch with industrial development of electronic components. After formulating conductive layer with sputtering on polyamide film, this product passes plating process and offers a various copper thickness (2~8㎛) that meets customers’ options.

|

Excellent Peel Strength and Dimensional Stability enable precise fine pitch design. |

|

Outstanding flexibility allowing for more design freedom in flexing applications. |

|

No adhesive to remove from laser-cleared openings or plated through holes. |

|

High heat resistance for ease operation and lead-free soldering process. |

|

Low stiffness to eliminate spring-back problems, and capable for smaller gap design. |

|

Low humidity absorption. |

APPLICATIONS

LEXFLEX 2L- Double Sided laminates:

|

High density flex circuits |

|

Chip on film (COF) substrate |

|

PDP driver IC packaging |

|

Tape automatic bonding (TAB) |

|

Ball grid array (BGA) |

|

Chip scale packaging (CSP) |

|

Traditional flex circuits |

|

Multi-layer rigid-flex wiring |

Specification of LEXFLEX DS

Model |

A Side Cu Thickness |

PI Thickness |

B Side Cu Thickness |

Core Diameter |

DS-1025 |

10㎛ |

25㎛ |

10㎛ |

3" / 6" |

DS-8025 |

8㎛ |

25㎛ |

8㎛ |

DS-8125 |

8㎛ |

12.5㎛ |

8㎛ |

| DS-6125 |

6㎛ |

12.5㎛ |

6㎛ |

DS-6025 |

6㎛ |

25㎛ |

6㎛ |

DS-2025 |

2㎛ |

25㎛ |

2㎛ |

DS-2125 |

2㎛ |

12.5㎛ |

2㎛ |

| LEXFLEX Film Width: 250mm / 500mm |

Property of LEXFLEX DS

Property

|

Unit |

Value |

Peel Strength

|

As Received |

Kgf/cm |

≥ 0.8 |

| After Soilder |

≥ 0.4 |

Dimensional

Stability

|

MD |

% |

± 0.04 |

| TD |

Solder Float (288°C)

IPC-TM-650.2.4.13

|

sec |

≥10 |

Dielectric Constant

(Dk @ 1GHz)

|

|

3.8 |

Tensile Strength

IPC-TM-650.2.4.4 |

MPa |

≥ 480 |

Tensile Modulus

IPC-TM-650.2.4.4 |

Gpa |

25 |

Z Axis Elongation

50C-260C

|

% |

2.3 |

Volume Resistivity

IPC-TM-650.2.5.17

|

MΩ·cm |

1012 |

Z-CTE (Before Tg)

IPC-TM-650.2.4.41

|

ppm/°C |

35 |

Moisture Absorption (100°C RH)

E-24/50+D-24/23

|

% |

0.15 |

| Flammability |

UL- 94 |

V - 0 |

* Above data are based on customer request are subject to change.

|

![]()